PRODUCT

PRODUCTS

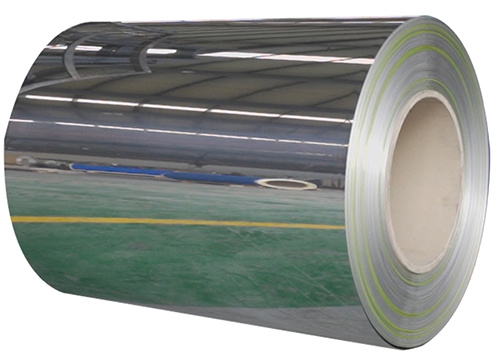

Alton® Mirror Aluminum Sheet & Coil

The Description Of Mirror

Alton® mirror aluminum plate is made of high end basic material with special rolling process, and after continuous mirror rolling process of coil, its reflectivity is improved and the surface is as smooth as a mirror.and the maximum total reflectivity can reach 86%. Under the irradiation of natural light or light, the mirror aluminum plate will concentrate the light around to form a dazzling light. At the same time, it can quickly reflect the heat energy projected on its surface.

Advantage Of Mirror Aluminum

Technical Parameter Of Mill Finish Aluminum

Alloy:1060/1070/3003/8014

Temper:O/H14/H16/H18

Reflection:86%

Finish:Mill Finish

Technical Parameter

| Alloy |

1070 H24 |

Standard |

GB Standard |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Tensile Strength/Mpa |

Yield strength/Mpa |

Elongation/% |

||||||||

| 191-193 |

175-177 |

7.0-8.0 |

||||||||

|

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Ni |

Zn |

Ti |

Other |

Al |

|

0.062 |

0.141 |

0.001 |

0.003 |

0.007 |

0.002 |

- |

0.005 |

0.0204 |

- |

99.70 |

|

Total Reflectance |

86% |

|||||||||

|

Alloy |

8014 O |

Standard |

GB Standard |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Tensile Strength/Mpa |

Yield strength/Mpa |

Elongation/% |

||||||||

|

111-112 |

73-75 |

31-33 |

||||||||

|

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Ni |

Zn |

Ti |

Other |

Al |

|

0.186 |

1.246 |

0.049 |

0.36 |

<0.001 |

0.004 |

<0.001 |

<0.001 |

0.008 |

/ |

other |

|

Total Reflectance |

86% |

|||||||||

Alton® Anodized Mirror Aluminum

A100

Mirror Sliver

A100

Mirror Sliver

A100

Mirror Sliver

Technical Parameter

|

Grade/Temper |

1085-H18/1090-H18 |

|---|---|

|

Thickness |

0.2~1.0mm |

|

Width |

20-1300mm |

|

Surface Process |

Continuous Anodizing |

|

Surface |

Mirror, Bright, Reflective |

|

Color |

Silver, light gold, dark gold, bronze mirror, gray mirror, black mirror, rose gold |

|

Film Thickness |

Indoor≥5µm,Outdoor≥15µm |

|

Hardness |

≥6H |

|

Total Reflectivity |

≥86% |

|

Color Difference |

No color difference by visual inspection, and the color difference value of the same aluminum coil △E≤2.0 |

|

Gloss |

Deviation of the same batch is smaller than 15 |

|

Hole Sealing Quality |

≤30 mg/ d㎡ |

|

Rainbow Degree |

Low |

|

Corrosion Resistance |

Indoor plate (more than 72 hours 5%NaCl spray test); Outdoor plate (more than 1000 hours 5%NaCl spray test) |

|

Resistance to Accelerating Weathering |

Test Time≥4000 h,Color Difference △E≤5.0,Other aging property is not less than 0 grade. |

|

Standard |

EN 573-3 ,T/CBMF113-2021 |

|

Alloy |

1085 H18 |

Reflectance |

86% |

Standard |

EN485/2 |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Tensile Strength/Mpa |

Yield strength/Mpa |

Elongation/% |

||||||||

|

169 |

161 |

4 |

||||||||

|

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Ni |

Zn |

Ti |

Other |

Al |

|

0.035 |

0.047 |

0.001 |

0.001 |

0.0 |

0.0 |

0.002 |

<0.01 |

0.02 |

- |

≥99.85 |

Advantage Of Anodized Mirror Aluminum

The anodic layer will never crach or peeled off.

86% reflection

Good Corrosion Resistance

100% Recyclable

Non-combustible

Anti-fingerprint

Alton® High Reflective Mirror

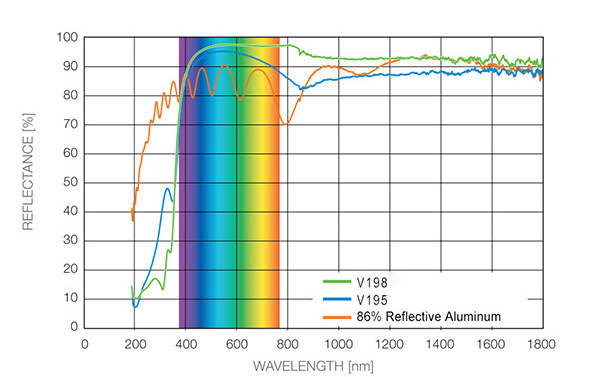

The coating system are applied to an electrochemically brightened high purity aluminum substrate coil, and start with an anodized base coated which gives a hard support minimize abrasion damages. The strip is then treated under vacuum specially developed processes to maximize coating adhesion and depending on the product type, is vacuum coated with a super pure reflection layer of either 99.95% pure aluminum (V195) or 99.9% pure sliver (V198)

Technical Parameter

|

Product |

Type |

Reflection layer |

reflectance [%] |

Specular reflectance [%] |

Diffuse reflectance [%] |

Alloy |

Temper (hardness) |

Min. tensile strength [MPa] |

Min. yield strength [MPa] |

Min. [%] elongation A5A10 |

Class efficiency |

||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ASTM E 1651 |

DIN 5036-3 |

60° long |

60° trans |

DIN 5036-3 |

EN 16268 |

||||||||

|

V195 |

high specular |

99.99% pure aluminum |

≥ 95 |

≥ 95 |

91 |

91 |

< 6 |

1085 |

H18 |

125 |

105 |

2 |

A |

|

V198 |

high specular |

99.99% pure aluminum |

≥ 98 |

≥ 98 |

93 |

93 |

< 11 |

1085 |

H18 |

125 |

105 |

2 |

A+ |

These reflection layers are over laid with a dual layer oxide system tuned for maximum visible reflection enhancement. This serves to increase the overall reflectivity provided by the metallic layers and adds protection against damage degradation.

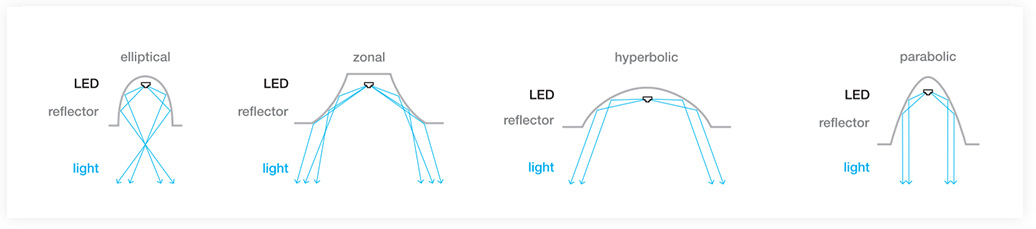

Multiple reflection in an optical reflector system can greatly reduce light output if the surface do not have the highest reflective.

|

Characteristic |

|||||

|---|---|---|---|---|---|

|

Laser |

Code |

Glare |

Influence of shape |

Application |

Micro-scope |

|

|

V195 |

Perfect Optimum beam control |

Very high |

Linear, lighting spot lighting, louvre, batwing, daylighting |

|

|

Loss per reflection |

Increase in performance |

|

|---|---|---|

|

V195 |

< 5% |

+ 15% |

|

V198 |

< 2% |

+ 20% |

combines the proven quality of the aluminum anodising process with the most advanced technology of surface coating under vacuum, know as PVD, know as PVD( Physical Vapour Deposition).

Alton® High Reflective Mirror Significantly improve the reflector optical performance and increase its efficiency up to 20%, . compared to the already high levels of anodized aluminum, thanks to its extraordinary reflectance. The higher of total reflection the higher the fixture efficiency. More internal reflections create greater difference.

|

Corrosion Tests |

||

|---|---|---|

|

UV resistance |

EN ISO 4892-3 |

< 0.5% reflectance change in 1000 h |

|

Neutral Salt Spray |

ASTM B 117 ISO 9227 NSS |

< 3% reflectance loss after 3000 h |

Graph showing reduction in light intensity with multiple reflections for 86%, 95% and 98% reflective materials

Comparison of spectral reflectance curves for V198 VS V195 and 86% reflective aluminum

Application Cases

Ceiling

lampshade

Car trim

Curtain Wall

Interior decoration

Brand Card

Subscribe to our newsletter to receive exclusive information about us and our services