PRODUCT

PRODUCTS

Aegis 3D™ Aluminum Core Composite Panel

Aegis3D is an improved panels developed by Our Company for the architectural facade, it is a new generation of advanced materials formed by pure metal materials, no glue, no plastic components, 100% environmental protection and fire prevention, much sturdier, provides a range of re-cladding options for building facades and internal wall cladding systems.

DIMENSION

|

THICKNESS |

WIDTH(mm) |

LENGTH(mm) |

FINISHES |

|---|---|---|---|

| 2440 |

Mill finish |

||

| 4mm | 1000 | 2700 |

Solid / Metallic coating |

| 5mm | 1220 | 3200 |

Sparkling coating |

| 6mm | 1250 | 4000 |

Brushed & Wood-look |

| 7mm | 1500 |

customized |

KEY BENEFITS

DEEMED NON-COMBUSTIBLE

Aegis3D is one of few aluminium

panels globally that is deemed

non-combustible under the BCA whentested to AS1530.1 & AS1530.3, No combustibility, No toxic fumes.

CODEMARK

Aegis3D is ABCB CodeMark certified to comply with the Building Code of Australia ensuring that customers are

specifying a quality assured product.

BUILDING BEAUTIFICATION

Unparalleled flatness, Ultra strong, Ultralight (4.5kg/㎡). Available in a variety of finishes and textures, from 3mm to 10mm thickness.

PAINT SYSTEM

Aegis3D uses the highly recognized PVDF KYNAR 500 or PPG & FEVE paints known for their high durability, providing the optimum resistance to weather and industrial pollution.

REDUCE MATERIAL&LABOR COSTS

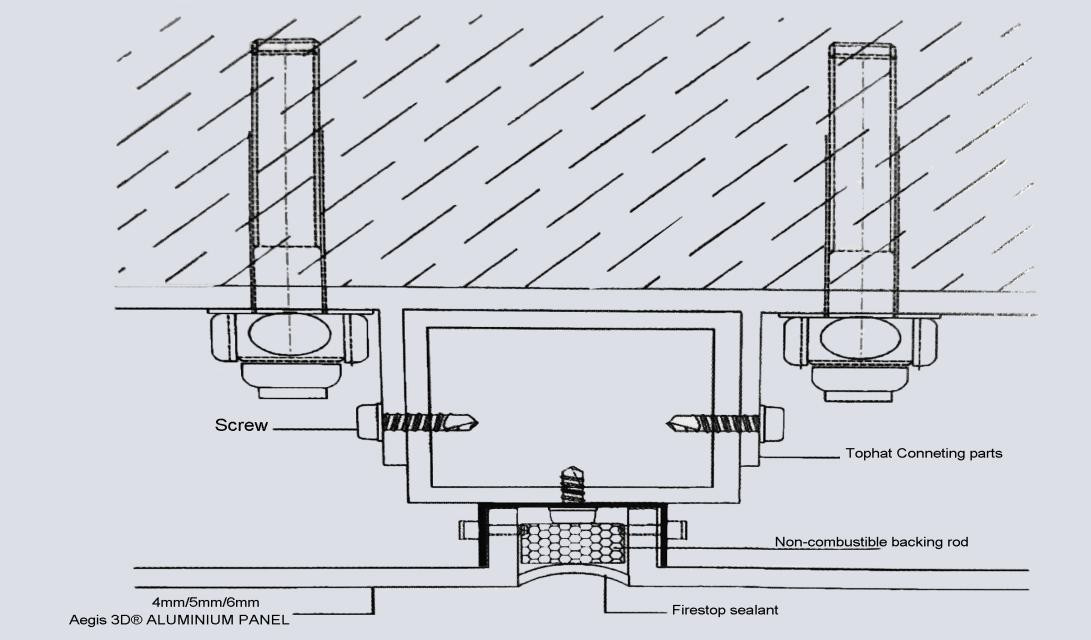

Coil continuous production technology, cost-effective and fast delivery, suitable for large projects. With pre-finished cassette panels, easy to assemble, reducing sheet metal, installation time and cost.

Warranty

Aegis3D™ has up to 15 year’s warranty when correctly installed and maintained.

FIRE RESISTANCE

|

TEST STANDARD |

ITEMS |

RESULT |

REGULARTORY INDICES |

|---|---|---|---|

|

NATA-AS1530.3 |

Ignitability Index |

PASS |

0 |

|

Spread of Flame |

PASS |

0 |

|

|

Heat Evolved |

PASS |

0 |

|

|

Smoke Developed |

PASS |

2 |

|

|

NATA-AS1530.1 |

DEEMED NON-COMBUSTIBLE MATERIALS |

||

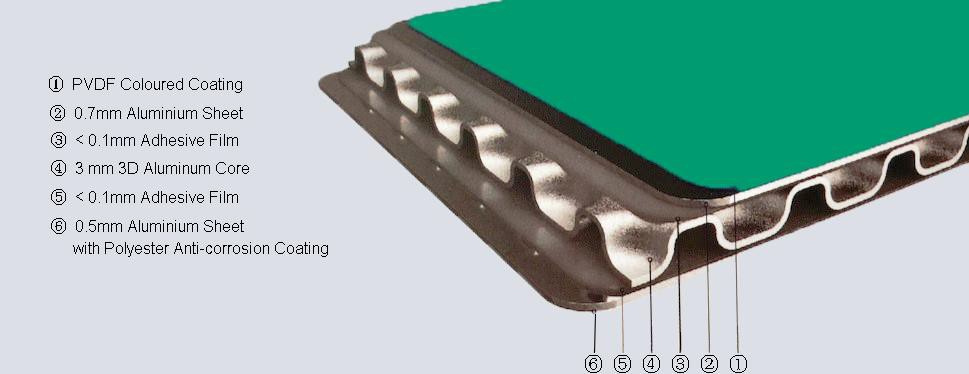

TYPICAL COMPOSITION

|

TEST ITEM |

REF STANDARD |

TEST CONDITION |

TEST RESULT |

|---|---|---|---|

|

Pane weight |

|

|

4.5 kg /m² |

|

Thickness |

|

|

4mm |

|

Width |

|

|

1250/1500 mm |

|

Thickness of aluminium face |

|

|

0.7mm |

|

Alloy |

|

|

3003 H24 |

|

Dry Film Thickness |

ASTM D1400 |

µm |

Avg,32; Min.30 |

|

Adhesion Original Sample After immersed in |

ASTM D3359-08 Method B |

Tape: 3M®610# Space 1mm |

5B |

|

5B,No visual change appeared on the coating |

|||

|

Gloss |

ASTM D2457-08 |

600 geometry |

31 |

|

Pencil Thickness |

ASTM D3363-05 |

Scratch hardness Pencil: Mitsubishi® |

2H |

|

Flexibility |

T-Bend, ASTM D4145 |

|

2 T-Bend; No pick-off |

|

Resistance to Acid and Alkali Reagent |

ASTM D1308-02(2007) |

Reagent:5% HCI Condition:23°C,24h |

Color difference ∆E*ab=0.2,No blistering or chalking appeared on the sample’s surface |

|

Reagent:5% NaOH Condition:23°C,24h |

Color difference ∆E*ab=0.3,No blistering or chalking appeared on the sample’s surface |

||

|

Core Shear properties |

ASTM C393/C393-11 |

|

Core shear ultimate strength:0.91 Mpa Facing stress:130.7 Mpa |

|

Tensile properties of facing aluminium panel |

ASTM E8/E8M-15a |

|

Tensile strength:172.9 Mpa Elongation: 8.4% |

|

Bending strength(Mpa) |

EN 485-2 ASTM D1781-98 (2012) |

|

186.5 N-mm/mm |

|

Peel strength after freeze-thaw cycle |

ASTM D1781-98 (2012) |

|

150 N-mm/mm |

|

Facing peel torque |

ASTM D1781-98 (2012) |

|

270 mm.N/mm |

|

Roll peel strength (N.mm/mm) |

EN 485-2 |

|

187.9N-mm/mm |

|

Flatwise compression strength (Mpa) |

EN 485-2 |

|

1.97 Mpa |

FIRE RESISTANCE

APPLICATION

Ceiling

Interior Decoration

Curtain Wall

COLOR

SL9010

Pure white

SL42G

High glossy white

SL9002

Stone White

SL7035

Foggy white

SL7001

Silver gray

SL7035

Light gray

SL7022

Deep gray

SL17

Black

SL40

Blue

SL50

Green

SL20

Yellow

SL30

Red

SL1401

Red Granite

White Granite

Coffee-colored reticulated granite

SL1403

White Granite

SL1404

White Marble

SL1301

Teak Texture

SL1302

Black larch Texture

SL1303

Annatto Texture

SL1304

White Larch Texture

SL1305

Bamboo Texture

SL1306

Maple Texture

SL1307

Sakuragi Texture

SL1308

Birch Texture

Subscribe to our newsletter to receive exclusive information about us and our services